Functional Diagrams form part of diagrams used In

Instrumentation. In our previous articles, we looked at Process Flow Diagrams, Process & Instrument Diagrams as well as Loop Diagrams.

In this article, we look at a unique form of

technical diagram for describing functions comprising a control system (e.g.

PID Controllers, Rate Limiters, Manual Loaders). The diagrams used to document

control strategies are termed as functional

diagrams. Note that, functional diagrams focus on the flow of information

within a control system rather than on the process piping or instrument

interconnections i.e. wires, tubes etc. The general flow of a functional

diagram is top-to-bottom, with the process sensing instrument (transmitter)

located at the top and the final control element (valve or variable-speed

motor) located at the bottom.

Functional Diagrams are all about the algorithms used

to control decisions, so no attempt is made to have the symbols arranged

to correspond with actual equipment layout.

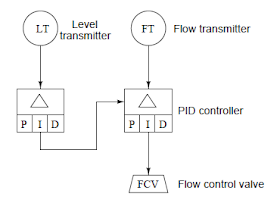

Let's consider a functional diagram shown below:

The above functional diagram shows a flow transmitter

(FT) sending a process variable signal to a PID Controller, which then sends a

manipulated variable to a flow control valve (FCV).

A cascaded control system, where the output of one

controller acts as the set-point for another controller to follow, appears in

functional diagram as shown below:

In the above cascaded control system, the primary

controller senses the level in a vessel, commanding the secondary (flow)

controller to maintain the necessary amount of flow either in or out of the

vessel as needed to maintain level at some point.

You can also read: How Loop Diagrams are used In Industrial Control

Functional diagrams may show varying degrees of

detail about the control strategies they document e.g. you may see the

auto/manual controls represented as separate entities in a functional diagram,

apart from the basic PID controller function. In the following Functional

Diagram, a transfer block (T) and two manual adjustment blocks (A) providing a

human operator with the ability to separately adjust the controller’s set point

and output (manipulated variables) and to transfer between automatic and manual

modes:

Rectangular blocks such as the Δ, P, I and D

shown in the diagram below represent automatic functions. Diamond-shaped

blocks such as A and T blocks represent manual functions which must be set by a

human operator. The Functional diagram also shows the presence of set point

tracking in the controller algorithm, a feature that forces the set point value

to equal the process variable value any time the controller is in manual mode.

A solid line in a functional diagram represent

analog (continuously variable) signals such as process variable, set point, and

manipulated variable. Dashed lines represent discrete (on/off) signal paths, in

this case the auto/manual state of the controller commanding the PID algorithms

to get its set point either from the operator’s input (A) or from the process

variable input (the flow transmitter: FT).

Don't miss out on key updates, join our newsletter list here.

No comments:

Post a Comment