One of the most common and useful pressure

measuring instrument used in most industrial measurement applications is the

differential Pressure transmitter. This device senses the difference in

pressure between two ports and outputs a signal representing that pressure in

relation to a calibrated range.

Differential Pressure transmitters constructed for

industrial measurement applications typically consists of a strong (forged

metal) body housing the sensing element(s), topped by a compartment housing the

mechanical and/or electronic components necessary to translate the sensed

pressure to a standard instrumentation signal e.g. 3-15 PSI, 4-20 mA, Digital

Fieldbus codes as shown in the below Diagrams:

In the below example of Rosemount differential

pressure transmitter, the pressure-sensing element is housed in the bottom half

of the device (forged-steel structure) while the electronics are housed in the

top half (the coloured, round, cast-aluminium structure)

Every differential Pressure (DP, d/p or ∆P)

transmitter has two pressure ports to sense different process fluid pressures.

These ports typically have ¼ inch female NPT threads to readily accept

connections to the process. One of these ports is labelled “high” and the other

is labelled “low’’. This labeling does not necessarily mean that the “high”

port must always be at a greater pressure than the “low’’ port. What these

labels represent is the effect any increasing fluid Pressure applied to that

port will have on the direction of the output signal’s change. Note that, a

differential pressure instrument responds only to differential pressure while

ignoring the common-mode pressure (gauge pressure common to both ports).

The most common sensing element used by modern DP

transmitters is the diaphragm. One side of this diaphragm receives process

fluid pressure from the “high’’ port while the other receives process fluid

pressure from the “low’’ port. Any difference of pressure between the two ports

causes the diaphragm to flex from its normal resting (center) position. This

flexing is then translated into an output signal by any number of different

technologies depending on the manufacturer and the transmitter model.

Differential Pressure (DP)

Transmitter Applications

The combination of two differential pressure ports

makes the DP transmitter very versatile as a pressure-measuring device. This

one instrument can be used to measure pressure differences, positive (gauge)

pressures, negative (vacuum), and even absolute pressures, just by connecting

the “high” and “low” sensing ports differently.

In every DP transmitter application, there must be

some means of connecting the transmitter’s pressure-sensing ports to the points

in a process. Metal or plastic tubes (or pipes) work well for this purpose, and

are commonly called impulse lines or gauge lines or sensing

lines. Typically these tubes are connected to the transmitter and to

the process by means of compression fittings which allow for relatively easy

disconnection and re-connection of tubes.

Key applications of DP transmitters

include:

Measuring Process Vessel Clogging

– We may use the DP transmitter to

measure an actual difference pressure across a process vessel such as a filter,

a heat exchanger, or a chemical reactor. The diagram below shows the use of a

DP transmitter to measure clogging of a water filter:

From the diagram above, you can see the high side

of the DP transmitter connects to the upstream side of the filter and the low

side of the transmitter to the down side of the filter. This way, increased

filter clogging will result in an increased transmitter output. Since the

transmitter’s internal pressure-sensing diaphragm only responds to differences

in pressure between “high” and “low” ports, the pressure in the filter and pipe

relative to the atmosphere is completely irrelevant to the transmitter’s output

signal. The filter could be operating at a line pressure of 15 PSI or 15000 PSI

– the only variable the DP transmitter measures is the pressure drop across the

filter. If the upstream side is 15 PSI and the downstream side is 14 PSI, the

differential pressure will be 1 PSI sometimes labelled PSID, where “D” is

differential. If the upstream pressure is 15000 PSI and the downstream pressure

is 14,999 PSI, the DP transmitter will still see a differential pressure of

just 1 PSID.

Measuring positive gauge pressure

– DP instruments can also serve as

gauge pressure instruments. If we simply connect the “high” side of a DP

instrument to a process vessel using an impulse tube, while leaving the “low”

side vented to atmosphere, the instrument will interpret any positive pressure

in the vessel as a positive difference between the vessel and the atmosphere.

Most DP instrument manufacturers offer gauge

pressure versions of their differential instruments with “high” side port open

for connection to an impulse line and the “low’’ side of the sensing element

capped off with a special vented flange, effectively performing the same

function as in the above figure.

Measuring absolute Pressure – Absolute pressure is defined as the difference

between a given fluid pressure and a perfect vacuum. We may build an absolute

pressure sensing instrument by taking a DP transmitter and sealing the “low”

side of its pressure-sensing element in connection to a vacuum chamber as shown below. This

way, any pressure greater than a perfect vacuum will register as a positive

difference.

Measuring Vacuum – The same principle of connecting one port of a DP

device to a process and venting the other works as well as a means of

measuring vacuum (Pressure below that of atmosphere). All we need

to do is connect the “low” side to the vacuum process and vent the ‘’high” side

to the atmosphere as shown below:

Any pressure in the process less than atmospheric

will register to the DP transmitter as a positive difference (with P-high greater

than P-Low ). Thus the stronger the vacuum in the process

vessel, the greater the signal output by the transmitter.

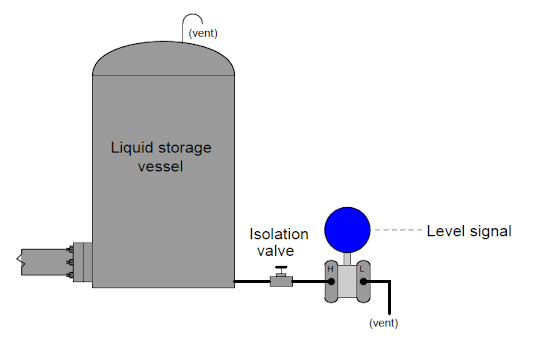

Inferring liquid level – Liquids generate pressure proportional to height

(depth) due to their weight. The pressure generated by a vertical column of

liquid is proportional to the column height (h), and liquid’s mass density (ρ),

and the acceleration of gravity (ɡ):

P=ρɡh

As the liquid in the vessel increases, the amount

of hydrostatic pressure applied to the transmitter’s ‘’high’’ port increases in

direct proportion. The width of the vessel is irrelevant to the amount of

pressure produced only the liquid height (h), density (ρ), and gravity (ɡ) are significant. Thus the transmitter’s increasing signal represents the

height of liquid inside the vessel no matter the size or shape of the vessel.

h = P/ρɡ

You can also read: Advantages and Disadvantages of Pneumatic Instruments

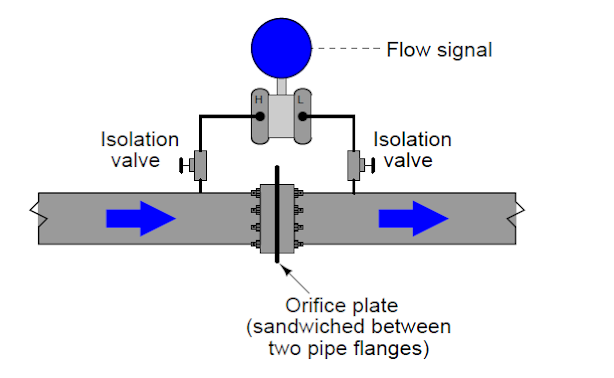

Inferring gas and Liquid Flow – DP transmitters are widely used in measurement of

fluid flow. Pressure dropped across a constriction in the pipe varies in

relation to flow rate (Q) and fluid density (ρ). So long as fluid density

remains fairly constant, we may measure pressure drop across a piping

constriction and use that measurement to infer flow rate. The most common form

of constriction is the orifice plate. This is a metal plate with a precisely

machined hole in the center. As fluid passes this hole, its velocity changes,

causing a pressure drop to form.

Since both ports of the transmitter connect to the

same process line, static fluid pressure within that line has no effect on the

measurement. Only differences of pressure between the upstream and downstream

sides of the constriction (orifice plate) cause the transmitter to register

flow.

Don't miss out on key updates, join our newsletter list here.

Thank you sir

ReplyDeleteA good summary and presentation of how a DP transmitter are being used and connected to a process, understanding these things are a big help when performing a DP transmitter calibration.

ReplyDelete