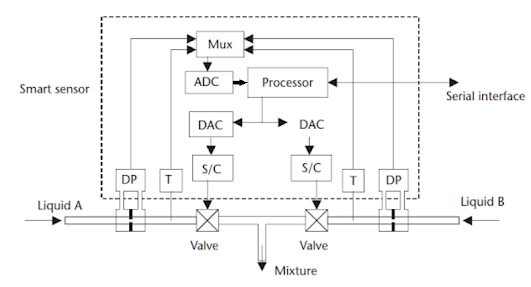

HART (Highway

Addressable Remote Transducer) communication protocol is a hybrid of both the

analog and digital industrial communication open protocol. HART communicates

digital data along the loop conductors in the form of AC signals

(audio-frequency tones) superimposed on the 4-20 mA DC current signals. A modem

built in the smart transmitter translates these AC signals into binary bits and

vice versa.

By

connecting a HART communication device at any point along the two-wire cable,

any instrument technician can easily configure the transmitter. Being able to communicate digital data over

the same wire pair as the DC power and analog signal makes it possible to communicate

self-diagnostics information, alarms, status reports; multiple process

variables for example temperature, density etc. to the control

system in addition to the original analog signal representing the main process

variable. The control system can also communicate to the transmitter using the

same digital protocol for example switch between measurement range sets etc. The

only limitation of digital communication is the data rate or speed, and not the

quantity of the data being transmitted.

The use of

HART doesn’t make any changes to the normal series connected circuit configuration

of the transmitter, DC supply, and resistor. A HART enabled transmitter is

equipped with a inbuilt digital microcontroller managing its functions, and

this microcomputer is able to send and receive digital data as AC signals

(current pulses in sending mode, voltage pulses in receiving mode) superimposed

on the same two wires carrying the 4-20 mA analog signals and DC power.

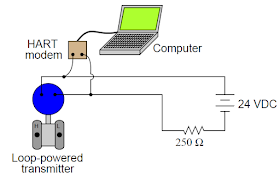

Any computer

device equipped with a HART modem, the configuration software, device

description, for that particular instrument may communicate with the HART

transmitter if connected in parallel with the transmitter’s loop power

terminals.

This external computer through the use of HART data transmission, can now monitor

details of the transmitter’s operation, configure the transmitter, make changes

to its measurement ranges among other additional functions.

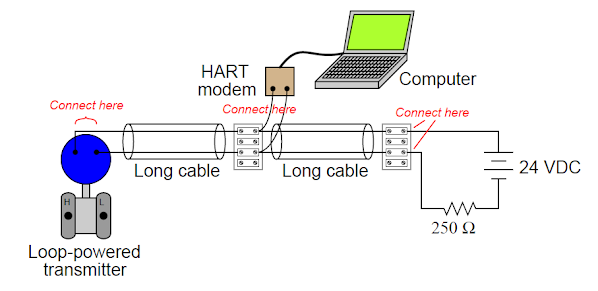

The HART

modem can be connected anywhere in the circuit electrically parallel to the

HART-enable transmitter’s terminals.

This flexibility

works to the advantage to the instrument technicians enabling them to connect the

HART configuration instrument at the most physical convenient location.

HART

communicators are battery powered, portable devices built specifically for

configuring HART-enabled field instruments. Like PCs they need to be updated

with DD files to be able to communicate with the latest models of HART-enabled

field instruments.

Key Features of HART communication

Protocol includes:

- Changes to field instruments ranges can be made remotely with the use of HART communicators.

- Field instruments may be programmed with identification data e.g. tag numbers, corresponding to plant-wide instrument loop documentation.

- Diagnostic data may be transmitted by the field device for example out of limit alarms, preventing maintenance alerts, self-test results etc.

- Technicians may use HART communicators to force field instruments into different manual modes for diagnostic purposes e.g. forcing a transmitter to output a fixed current so as to check calibration of other loop components, manually stroking a valve equipped with a HART capable positioner.

Merits of HART Protocol

HART

technology has allowed new features and capabilities to be added on to existing

analog signal loops without having to upgrade wiring or change all the

instruments in the loop.

Don't miss out on key updates, join our newsletter list here.

Demerits of HART Protocol

The main

disadvantage of HART data communication is the slow speed. Its bit rate of 1200 bits per second is slow

for modern standards.