Ultrasonic

Flowmeters measure the velocity of a flowing medium by monitoring the

interaction between the flow stream and an ultrasonic sound wave transmitted

through it.

You can also read:

Advantages of ultrasonic Flowmeters

Don't miss out on key updates, join our newsletter list here.

The main

techniques used are:

- Doppler

- Time of flight/Transit-time

Doppler Flowmeters

These types

of ultrasonic flowmeters use Doppler Effect which states that the frequency of

sound changes if its source or reflector moves relative to the listener or

monitor. The magnitude of the frequency change is an indication of the speed of

the sound source or sound reflector.

Doppler

flowmeter comprises a housing in which two piezoelectric crystals are potted,

one being the transmitter and the other a receiver. This whole assembly is

located on the pipe wall as shown below:

The

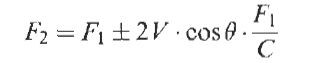

transmitter transmits ultrasonic waves of frequency F1 at an angle ϴ

to the flow stream. If the flow stream contains particles, entrained gas or

other discontinuities, some of the transmitted energy will be reflected back to

the receiver. If the fluid is travelling at a velocity V, the frequency of the reflected sound as monitored by the

receiver can be shown to be F2 such that:

Where C is

the velocity of sound in the fluid.

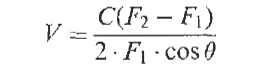

Rearranging

the equation:

Which show

velocity is proportional to the frequency change.

Applications of Doppler flowmeters

The Doppler

flowmeter is normally used as an inexpensive clamp on flowmeter. The only

operational constraints being that the flows stream must contain discontinuities

of some kind, without which the device won’t work. Note the device cannot

monitor clear liquids. For the Doppler flowmeter to work, the pipeline must be

able to transmit acoustic signals.

Doppler

flowmeter is mostly used as a flow switch or for flow indication where the

absolute accuracy is not required.

Time of Flight Flowmeters

Ultrasonic

flowmeters that use time of flight technique differ from Doppler flowmeters in

that they rely on transmission of an ultrasonic pulse through the flow stream

and therefore do not depend on the discontinuities or entrained particles in

the flow stream for operation.

The

principle of operation is based on the transmission of an ultrasonic sound wave

between two points, first in the direction of flow, and then in the opposing

flow. In each case the time of flight of the sound wave between the two points

will have been modified by the velocity of the flowing medium and the

difference between the flight times can be shown to be directly proportional to

the flow velocity.

The sound

waves are not generated in the direction of flow but at an angle across it as

shown below:

Pulse

transit times downstream T1

and upstream T2 along

the path length D can be expressed

as:

T1 = D/(C +

V) and T2 = D/(C –V), where C is the velocity of sound in the fluid and V is the fluid velocity.

Now, T = T1

– T2 = 2DV/ (C2 –V2) (equation 1)

Since V2 is very small

compared to C2 it can

ignored. It is convenient to develop the expression in relation to frequency

and remove the dependency on the velocity of sound C.

Since F1 = 1/T1 and F2 = 1/T2 and

the average fluid velocity Vav =

V/ (cosϴ)

Replacing T1 and T2 in equation 1

with respective Frequencies, we get:

F1 - F2

= (2Vav cosϴ)/D

The

frequency difference is calculated by an electronic converter which gives an

analog output proportional to average fluid velocity.

In practice,

the piezoelectric ceramic transducers used act as both transmitters and

receivers of the ultrasonic signals and thus only one is required on each side

or the pipe.

Typically

the flowmeter consists of a flow tube containing a pair of externally mounted

transducers and a separate electronic converter/transmitter. Transducers may be

wetted or non-wetted and consist of a piezoelectric crystal sized to give the

desired frequency (typically 1 – 5 MHz for liquids and 0.2 -0.5 MHz for gases.

You can also read:

Advantages of ultrasonic Flowmeters

The unique

advantage of ultrasonic flow measurement is the ability to measure flow through

the use of temporary clamp-on sensors rather than a specialized flow tube with

built in ultrasonic transducers.

Some modern

ultrasonic flowmeters have the ability to switch back and forth between Doppler

and transit-time (counter propagation) modes, automatically adapting to the

fluid being sensed. This capability enhances the suitability of ultrasonic flowmeters

to a wider range of process applications.

Limitations of Time of Flight Ultrasonic

Flowmeters

Due to the

fact that the flowmeter measures velocity across the center of the pipe, it is

susceptible to flow profile effects and care should be taken to ensure there is

sufficient length of straight pipe upstream or downstream of the flow tube to

minimize this kind of effects.

To overcome

this problem, manufacturers use multiple beam techniques where several chordal

velocities are measured and the average computed, but note that, since

ultrasonic flowmeters are easily affected by swirl and other large scale fluid

disturbances, it is advisable to ensure an approximately 10 upstream and

downstream diameters of straight pipe of the measurement flow tube, when installing

them, this helps to stabilize the flow profile.

Also since

this type of flowmeter relies on transmission through the flowing medium,

fluids with a high solids or gas-bubble content cannot be measured well using ultrasonic

meters.

Applications of Ultrasonic Flowmeters

Ultrasonic

flowmeters are used in various industrial process measurement applications, and

some of them include:

- Measurement of both conductive and non-conductive liquids

- Measuring aqueous liquids as well as extreme viscous oils

- Measuring multiple products e.g. allocation measurements in on/off loading

- The are used in all process industries: make up water, demineralized water, boiler feed water etc.

- They are also considered for custody transfer natural gas

Great! the detailed A to Z info about ultrasonicflow meterwas explained. Thanks for sharing. Keep posting...

ReplyDelete