Positive

displacement flowmeters have a cyclic mechanism designed to pass a fixed volume

of fluid through with every cycle.

Every cycle

of the meter’s mechanism displaces a precisely defined (positive) quantity of

fluid, so that a count of the number of mechanism cycles yields a precise

quantity for the total fluid volume passed through the flowmeter.

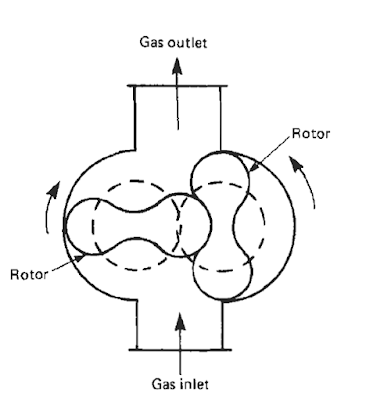

Example of

Rotary Displacement flowmeter is shown below:

Each shaft

revolution in a Rotary Displacement flowmeter represents a certain volume of

fluid that has passed through the meter.

Besides,

Rotary Displacement flowmeters, we have other types like Diaphragm meter

(Bellows type), Liquid sealed drum (wet gas meter), Pistons etc.

Advantages of using Positive Displacement

Flowmeters

Positive

displacement flowmeters are immune to swirl and other large-scale fluid

turbulence, and can be installed anywhere in a piping system. There is no need

for long sections of straight of straight-length pipe upstream or downstream as

with the case of Ultrasonic Flowmeters. Positive displacement flowmeters are also very

linear, since the mechanism cycles are directly proportional to fluid volume.

Limitations of Positive Displacement

Flowmeters

The sealing

surfaces of rotating mechanisms are subject to wear and accumulating

inaccuracies over time. The finely machined construction of a positive

displacement flowmeter can suffer damage from abrasive materials like grit

present in the fluid, meaning that these types of flowmeters are only used for

clean fluid flow streams.

You

can also read:

Applications of Positive Displacement

Flowmeters

Positive

displacement meters are commonly used for custody transfer of gas. Positive Displacement meters can measure high viscosity clean liquids as high as 1 Million centipoise, they also

find application in water flow measurement.

Don't miss out on key updates, join our newsletter list here.

No comments:

Post a Comment