Vortex

flowmeters are used to measure the flow of Gases, Vapours and liquids in

completely filled pipes. The measuring principle behind vortex flowmeters is

based on the Karman vortex street.

Advantages of using Vortex Flowmeters

Disadvantages of using Vortex Flowmeters

You can also read:

Industrial Applications of Vortex Flowmeters

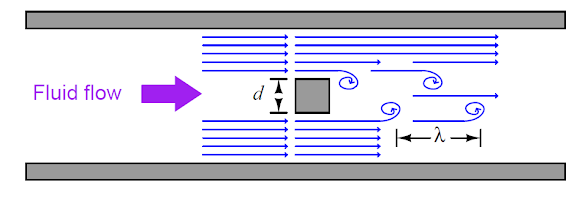

When a fluid moves with a high Reynolds number past a stationary object (a

bluff body) there is tendency for the fluid to form vortices on either side of

the object. Each vortex will form, then detach from the object and continue to

move with the flowing gas or liquid, one side at a time in alternating fashion.

This phenomenon is known as vortex shedding, and the pattern of moving vortices

carried downstream of the stationary object is known as a vortex street.

From the

research that was first done by Vincenc Strouhal then later on, by Theodore Von

Karman, It was established that the distance between the successive vortices

downstream of the stationary object is relatively constant, and directly

proportional to the width of the object, for a wide range of Reynold number

values.

If consider

these vortices as crests of a continuous wave, the distance between vortices

may be represented by the symbol of wavelength ‘’lambda’’ (λ)

d- Object width

λ- Vortex street wavelength

S- Strouhal

number

(λS = d) where S is approximately equal to 0.17

The wavelength (λ) is equivalent to d/0.17

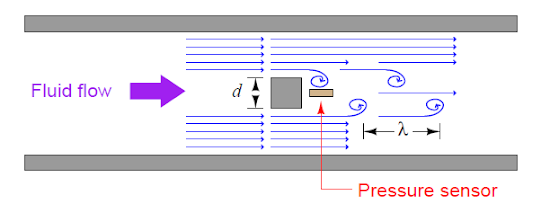

If a

differential Pressure sensor is installed immediately downstream of the

stationary object in such an orientation that it detects the passing vortices

as pressure variations, an alternating signal will be detected.

The

frequency of this alternating pressure signal is directly proportional to fluid

velocity past the object, since the wavelength is constant.

Using the

classic frequency velocity wavelength formula common to all travelling waves; λf = v, and since we know the wavelength from the above, we

may substitute this into this formula.

Velocity (v)

= wavelength (λ) x Frequency (f),

Velocity (v)

= d/0.17 x f

Therefore,

frequency (f) = 0.17v/d

Therefore

the stationary object and pressure sensor installed in the middle of the pipe

section constitute a flowmeter called a Vortex flowmeter; the output frequency

of a vortex flowmeter is linearly proportional to volumetric flow rate.

The pressure

sensors used in vortex flowmeters, are typically piezoelectric crystals.

The

relationship between sensor frequency (f) and volumetric flow rate (Q) may be

expressed as proportionality, with the letter k used to represent the constant

of proportionality for any particular flowmeter:

Therefore, f

= kQ

Where f =

Frequency of output signal (Hz)

Q =Volumetric flow rate (e.g. liters per

second or gallons per second etc.)

K = ‘’K’’ factor of the vortex shedding

flow tube (e.g. pulses per gallon or pulses per a liter)

Each vortex

flowmeter has a ‘’k’’ factor relating to the number of pulses generated per

unit volume passed through the meter.

Counting the

number of pulses over a certain time span yields total fluid volume passed

through the meter over the same time span, making the vortex flowmeter readily

adaptable for totalizing fluid volume.

The direct

proportion between vortex frequency and volumetric flow rate means vortex

flowmeters are linear-responding instruments.

Advantages of using Vortex Flowmeters

Vortex

flowmeters have a wide turn down ratio or a wide range of flow measurement. They

do not require signal characterization to function properly. Since they have no

moving parts, they do not suffer the problems of wear and lubrication facing

turbine or positive displacement meters and can measure erratic flows.

Disadvantages of using Vortex Flowmeters

The

flowmeter may stop working below certain flow rate, known as low cut off. This

is because, at low flow rates i.e. laminar flow (low Reynolds number values),

fluid viscosity becomes sufficient to prevent vortices from forming, causing

the vortex flowmeter to register zero flow even when there may be some flow in

the pipe.

You can also read:

Industrial Applications of Vortex Flowmeters

Vortex flowmeters are used in measurement of saturated steam and

super-heated steam. They are also used in measurement of consumption of industrial gases. You will find them commonly used in Steam boiler monitoring, measurement of consumption in compressed air systems, heat metering in steam & hot water and lastly in SIP and CIP processes in the food, beverage and pharmaceutical industries among other areas not mentioned here.

Don't miss out on key updates, join our newsletter list here.

No comments:

Post a Comment