Flow control

valves forms an important component of any industrial instrumentation system and

control system. When a change in a measured variable with respect to a

reference has been sensed, it is necessary to apply a control signal to an

actuator to make the corrections to an input controlled variable for example via

a valve bringing the measured variable back to its preset value.

Globe Valve

You can also read:

Butterfly Valve

In most

cases, any change in the variables e.g. Temperature, Pressure, and Level) can

be corrected by controlling the flow rates. The actuators used to control valves for flow

rate control can be electrically, pneumatically or hydraulically controlled.

Actuators

can be self-operating in local feedback loops. The two most common types of

variable devices used for flow control are the globe valves and the butterfly

valve.

Globe Valve

Let’s

consider the following diagram:

The actuator

controlling the valve can be controlled or driven electrically, pneumatically

or hydraulically.

The actuator

determines the speed of travel and the distance that the valve shaft travels.

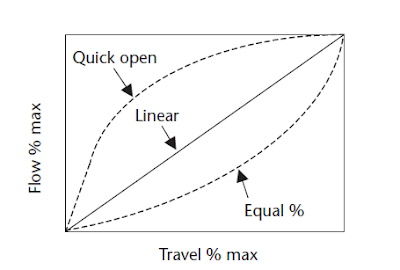

We have various

Globe valve configurations. The globe valve can be designed for quick opening

operation, for equal percentage operation or with a linear relationship between

flow and lift or any combination of these. We also have other configurations

like two-way valve (diverging type) and three-way valve.

The

selection of the type of control plug depends on a careful analysis of the

process characteristics. If the load changes are linear, then a linear plug

should be used; conversely, if the load changes are nonlinear, then a plug

with the appropriate nonlinear characteristics should be use.

Other types

of Globe valves include: Needle valve, which has a diameter of 1/8 to 1 inch

size. The balanced cage-guided valve and the split body valve.

Note: Globe

valves aren’t suitable for use with slurries.

You can also read:

Butterfly Valve

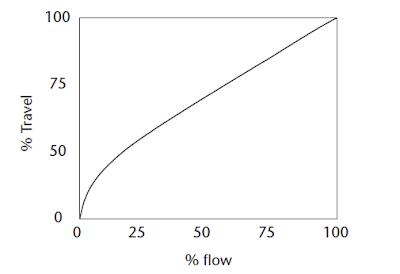

A butterfly

valve consists of a cylindrical body with a disk the same size as the internal

diameter of the valve body, mounted on a shaft that rotates perpendicular to

the axis of the body.

The relationship

between flow and lift is approximately 50 % open, after which it is linear.

Butterfly

valves offer high capacity at low cost. They are also simple in design, are

easy to install and have tight closure. The torsion force on the shaft

increases until the valve is open 70° then reverses.

Butterfly

valves have a limited pressure range, and are not used for slurries.

Don't miss out on key updates, join our newsletter list here.

Butterfly valves are versatile flow control devices known for their simplicity and efficiency. With a quarter-turn operation, they offer quick and precise control of fluid or gas flow. Their compact design and lightweight construction make them easy to install and maintain, making butterfly valves a popular choice in various industrial applications. Whether in water treatment plants or HVAC systems, these valves provide reliable and cost-effective solutions for regulating flow.

ReplyDeleteButterfly Valve Manufacturer