We have different ways of measuring 4-20 mA loop current. Normally we use the standard milliammeter to measure the loop current but downside of this method, is you have to break the circuit, at some point to connect the meter in series with the current, which means interrupting the flow of information conveyed by that current. That why we have other methods you can use to measure the loop current without interrupting the process, you can use:

- Clamp-on milliammeter

- Test" diodes

- Shunt resistors

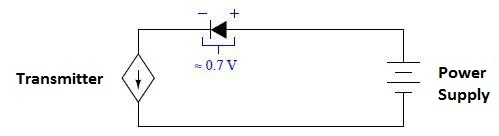

In this article we discuss the use of ''Test'' diodes to measure loop current in process measurement and control systems. The use of rectifying diode that is originally in

the loop circuit when it is commissioned to measure 4-20 mA loop signal ensures no interruption. A ”test”

diode may be placed anywhere in series within the loop in such a way that it

will be forward-biased. During normal operation, the diode will drop

approximately 0.7 volts, as it is typical for any silicon rectifying diode when

forward biased. To illustrate this, the following schematic diagram shows such

a diode installed in a 2-wire transmitter loop circuit:

|

| Fig 1 |

If you connect a milliammeter in parallel with this

diode, (as shown in Fig 2), however, the very low input resistance of the ammeters, '' shorts past'' the diode and prevents any substantial voltage drop from forming across

it. Without the necessary forward voltage drop, the diode effectively

turns off and conducts 0 mA, leaving the entire loop current to pass through

the ammeter.

|

| Fig 2 |

When you disconnect the milliammeter, the requisite

0.7 volt drop appears to turn on the diode, and all the loop current flows

through the diode again. From this, you can see there is no interruption

meaning that the technician may take current measurements this way with no

worries about generating false process variable indications, setting off alarms

or upsetting the process.

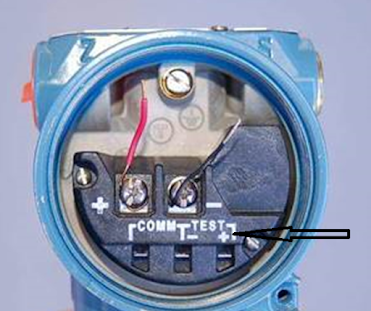

Such a diode may be installed at the nearest

junction box, between terminals on a terminal strip, or even incorporated into

the transmitter itself. If you check carefully, some process transmitters have

an extra pair of terminals labelled “Test” for this exact purpose. A diode is

already installed in the transmitter, and these “Test” terminals serve as

points to connect the milliameter across it. An example is shown of a Rosemount differential pressure transmitter:

|

| Fig 3 |

Take note of the test points labelled “TEST” below

and to the right of the main screw terminals where the loop wiring attaches.

Connecting an ammeter to these two test points allows for direct measurement of

the 4-20 mA current signal without having to undo any wire connections in the

circuit.

Transmitters equipped with analog meter movements

for direct visual indication of the 4-20 mA signal usually connect the analog

milliameter in parallel with such a diode. The reason for doing this is to

maintain loop continuity in the event that the fine-wire coil inside the

milliameter movement were to accidentally break open.

Don't miss out on key updates, join our newsletter list here.

No comments:

Post a Comment