In the previous post, we looked at Process Flow

Diagrams (PFDs), where we indicated that a PFD represents a big

picture of the entire process. In this post, we look at the Process and

Instrument Diagrams (P & IDs), where we will try to get more details that

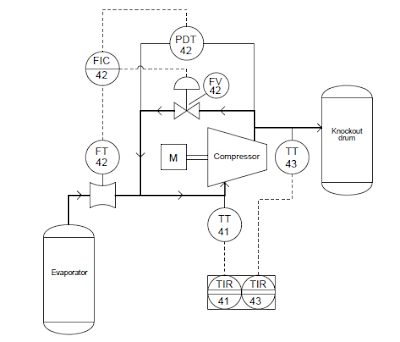

weren’t shown in the PFD. Let's consider the compressor control system diagram

below:

From the above, we can see that there is more

instrumentation associated with the compressor than just a flow transmitter. We

have the differential pressure transmitter (PDT), a flow indicating controller

(FIC), and a recycle control valve (FV42), that allows some of the vapor coming

out of the compressor discharge line to go back around the compressor suction line. Also, we have a pair of temperature transmitters (TT41 &

TT43) reporting suction and discharge line temperatures to an indicating

recorder.

Additional details emerge in the P & ID above,

the flow transmitter, flow controller, pressure transmitter and flow valve all

bear a common number 42. This common, ”loop number” indicates these four

instruments are all part of the same control system. An instrument with any

other loop number is part of a different control system, measuring and/or

controlling some other function in the process like the two temperature

transmitters and their respective recorders, bearing the loop numbers 41 and

43.

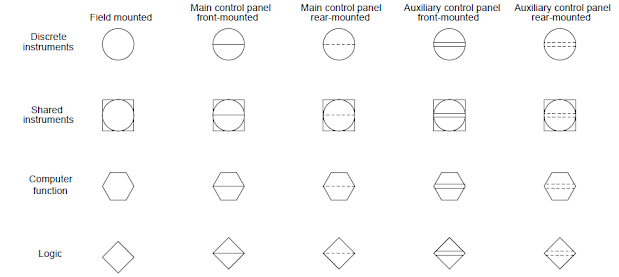

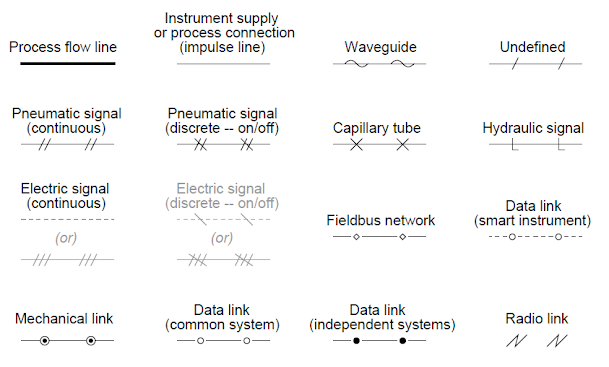

The other information we can derive from the P

& ID above, are the different instrument ” bubbles” used. Some of the

bubbles are just open circles, while others have lines going through the middle

as shown below:

Each of these symbols have meaning according to the

ISA ( Instrumentation, Systems and Automation Society).

The type of “bubble” used for each instrument tells

us something about its location. The rectangular box enclosing box enclosing

the temperature recorders (TIR 41 and TIR 43) shows they are part of the same

physical instrument i.e. this indicates that there is really only one

temperature recorder instrument, and that it plots both suction and discharge

temperatures (most likely on the same trend graph). This suggests that each

bubble may not necessarily represent a discrete, physical instrument, but

rather an instrument function that may reside in a multi-functional device.

The

P & ID shows more details than PFD, but we cannot see other details like

the cable types, wire numbers, terminal blocks, junction boxes, instrument

calibration ranges, failure modes, power sources etc. To examine this level of

details, we need to look at the loop diagram.

Don't miss out on key updates, join our newsletter list here.