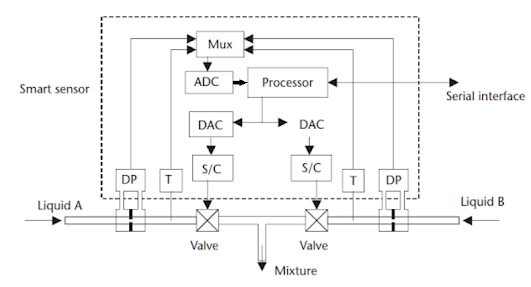

A smart

sensor is the integration of a processor directly into the sensor assembly,

which gives direct control of the actuator and digital communication to a

central controller i.e. it, allows for the direct conversion of an analog

signal to a digital signal, conditioning of the signal, generation of a signal for

actuator control, and diagnostics.

You can also read:

Let’s

consider the following diagram:

The above

diagram represents a process where they are mixing two liquids in a fixed

ratio, the flow rates of both liquids are monitored using differential pressure

sensors (DP). The temperatures of the liquids are monitored to correct the flow

rates for density changes and any variations in in the sensitivity of the DP

cells using Temperature sensors (T),

The

electronics in the smart sensor contains all the circuits necessary to

interface to the sensor, amplify and condition the signal, and apply

proportional, integral and derivative action (PID).

When the

usage is varying, the signals from the sensors are selected in sequence by the

multiplexer (Mux), and then converted by the ADC (Analog to Digital Converter)

into a digital format for the internal processor.

After signal

evaluation by the processor, the control signals are generated, and the DACs

(Digital to Analog Converters) are used to convert the signal back into analog

format for actuator control.

Communication

between the central control computer and the distributed devices is via a

common serial bus.

The serial bus

or Fieldbus is a single twisted pair of leads used to send the set points to

the peripheral units and to monitor the status of the peripheral units. This

enables the processor in the smart sensor to receive updated information on

factors such as set points, gain, operating mode etc. and to send status and

diagnostics information back to the central computer

Smart

sensors are available for all the functions required in process control, such

as flow, temperature, humidity, pressure and level control.

The

implementation of smart sensors has the following advantages over central

control systems:

- Smart sensors use a common serial bus eliminating the need for discrete wires to all sensors, greatly reducing the wiring cost, large cable ducts, and confusion over lead destination during maintenance or upgrades.

- The smart sensor takes over the conditioning and control of the sensor signal reducing the load on the central control system, allowing for faster system operation.

- Uniformity in programming means that the program only has to be learned once and new devices can be added to the bus on a plug and play basis.

- Individual controllers can monitor and control more than one process variable.

- Smart sensors have a powerful inbuilt diagnostics, which reduces commissioning, and start-up costs and maintenance.

- The set points and calibration of a smart sensor are easily changed from the central control computer.

- Direct digital control provides high accuracy, not achievable with analog control systems and central processing.

- The cost of smart sensor systems is higher than the conventional systems, but when the cost of maintenance, ease of programming, ease of adding new sensors is taken into account, the long term cost of sensor system is less.

Limitations of Smart sensors

Since these sensors are connected to a common serial bus, if the bus

fails, the total system is down, which is not the case with discrete wiring; this

problem can be prevented by use of a redundant backup bus.

Don't miss out on key updates, join our newsletter list here.