We have so many people with questions as to what

are the similarities and differences if any between PLC and DCS systems. We

will try to describe the working of these two systems and in the process help

you understand the functions of each system.

Do you have comments or questions on PLC or DCS? Feel free to post them in the comments section below.

Initially DCS was focused only on process control

with analog signals that were used as main control system in process industries

like Refining, Chemicals, and Petrochemicals etc. while PLC was focused on

discrete automation with discrete on-off signals, that were used for example in

Factory assembly lines and bottle lines but today DCS supports discrete I/O and

some logic functions and PLCs support analog I/O with some control functions.

In some instances Both PLC and DCS are used in the same plant i.e. PLCs are

used on separate units on a plant floor which are then integrated with main

plant-wide DCS for Control and Monitoring.

Let us now look at each system separately to help

us understand more how they work.

PLC

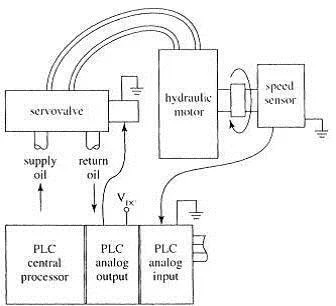

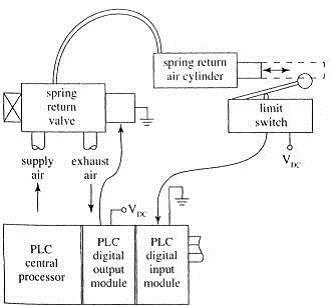

Programmable Logic Controllers (PLCs) comes in

different sizes which means various I/O and program capacities. Smallest sized

PLCs are typically referred to as nano PLCs, micro PLCs and mini PLCs. They

have fixed I/O and mainly used in stand-alone applications.

Large PLC support redundancy for CPU, power supply

and possibly the control network, but typically not for I/O cards though there

are large PLCs that support I/O redundancy by using duplicate I/O-subsystems

with separate backplanes where the field instruments are wired in parallel to

both I/O subsystems. The control network is typically a standard industrial

Ethernet application protocol over Ethernet media and IP. The Field cabling

comes directly onto the I/O card.

PLC usually support very fast scan times as

required in discrete manufacturing but PID loops add to the CPU load, much more

than discrete load thus making the scan time slower.

Loops are not handled individually in a PLC.

Addition or change to loop requires a download of the entire program which

affects other loops in the CPU as well.

PLCs are built around a given native protocol, this

maybe: PROFIBUS, Modbus, DeviceNet etc. The PLC comes with its own native

interface cards for native protocol supported by the PLC maker but relies on

third-party interface cards for other Fieldbus protocols. The engineering

software therefore automatically configures the communication interface card

for the native protocol.

You can also read:

Key Points to note on PLC

PLCs were designed to eliminate assembly-line

relays during model changeovers. PLC is easier to change than relay panels;

this has reduced the installation and operational cost of the control system

compared with electromechanical relay systems.

|

| BLOCK DIAGRAM OF A PLC SYSTEM |

PLC offers the following advantages:

- Ease of programming and reprogramming in the plant

- Programming language is based on relay wiring symbols familiar to most plant electrical and instrumentation personnel

- High Reliability and minimal maintenance

- Small physical size

- Ability to communicate with computer systems in the plant

- Moderate to low initial investment cost

- Available in modular designs

DCS

Distributed Control System (DCS) supports

redundancy for controllers, power supply and control network as well as

redundant I/O cards including fieldbus interface cards in the same backplane.

The control network supports peer-to-peer communication between controllers.

The control network is typically a proprietary application protocol over

Ethernet media and IP. The field cabling in DCS lands on a Field Terminal

Assembly (FTA) where a special system cable with a connector takes the signals

to the I/O card.

Loops in a DCS are executed individually. The scan

time in a DCS is set individually for each loop. Most loops run at 1000ms although

250ms is common for pressure and flow loops in refining and petrochemicals and

even 100ms is also possible. The scan time is constant, and does not change

with task loading. This is important for PID control and time-based functions

such as integration/totalizing and lead-lag dynamic compensation.

Loops in a DCS are managed individually. A change

and download to one loop doesn’t affect the other loops.

A DCS has an integrated development environment

where I/O control strategy and operator graphics are created together and

stored in a single database. This means once a tag is created in the DCS it

automatically becomes available everywhere in the system with the same human

readable tag name for use in basic control, advanced control, graphics, faceplates,

trending, alarming, and turning etc. Without mapping data through

registers or other tag names makes it easy to do changes or additions.

The Sensor & Actuator level “H1” Fieldbus

network supported by DCS is basically FOUNDATION fieldbus for instrumentation

and PROFIBUS-DP for motor controls.

The DCS comes with its own native Fieldbus

interface cards. The engineering software therefore automatically configures

the communication interface cards for the variables used in the control

strategy and graphics.

Key Points to Note on DCS

DCS is miniaturized version of the multitasking,

multivariable, multi-loop controller used for process control. It is

functionally and geographically processing distributed system. Equipment making

up a DCS is separated by function and is installed in two different work areas

of a processing installation. Equipment for operator to monitor process

condition and to manipulate the set point of the process operation is located

in a central control room; from where the operator can view information

transmitted from the process area and displayed on a video display unit and can

change control condition from a keyboard. DCS systems are suitable for the

following processes:

- Where a single centralized system is not adequate i.e. Power, Steel, Pulp & Paper plants, Fertilizer etc.

- Processes of different level of hierarchy

- Processes which can be divided into different and functionally independent sections, based on functional scope and geographical distribution

DCS offers the following Advantages:

- Compact to contain ON/OFF controllers

- Reduced complexity and easy expandability

- High Speed of the control processing

- Control Algorithms changes do not call for hardware changes

- Continuous trend data is available

- User friendly but higher data security

- Plant data are transparent on the network

- Sequential, batching and feedback control are possible

Don't miss out on key updates, join our newsletter list here.

Differences between PLC and DCS based

Systems

PLC

|

DCS

|

Redundancy not possible or

limited

|

Redundancy possible at every

level

|

It is used for low loop count

|

It is used for any loop count

|

Performance drops with

increasing loop count

|

No change in performance with

increasing loop count

|

Purely free running mode

|

Highly efficient multitasking

mode

|

Analog processing simulated

through digital computer

|

Analog processing done in real

frequency domain function

|

No interplant connectivity

|

Fully Functional Inter-plant

connectivity

|

Individual database for every

node

|

System-wide global database

|

Typical performance: 100 PID

loops/sec

|

Typical Performance: More than

1000 PID loops/sec.

|

Do you have comments or questions on PLC or DCS? Feel free to post them in the comments section below.