Displacer level transmitter is used in Process measurements

of liquids across many process industries. In this article we discuss the

Principle of operation and industrial level applications that displacer

transmitter technology offers.

Principle of Operation

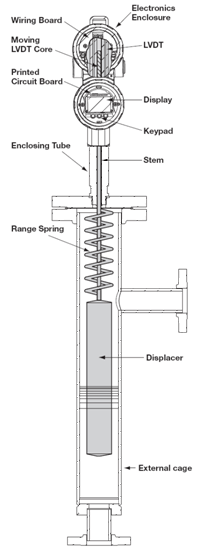

Operation is based on buoyancy force. The buoyancy

force works on the displacer which will vertically move in (increasing liquid

level) and out (decreasing liquid level) the linear differential transformer

(LVDT). Due to this movement, voltages are induced in the secondary winding of

the LVDT. These signals are then processed in the electronic circuitry and used

to control the output signal.

Industrial Applications

Displacer transmitters are ideal solution for

liquids or slurries, clean or dirty and light hydrocarbons to heavy acids with

a specific gravity (SG) of 0.23 to 2.20.

Displacer transmitter technology works well in a

variety of vessels including process & storage, bridles, bypass chambers,

interfaces, sumps and pits up to unit pressure and temperature ratings. They

can also handle most liquid conditions including varying dielectric, vapors,

turbulence, foam, buildup, bubbling or boiling and high fill/empty rates.

Some of the specific industrial applications include:

Boiler control – The displacer unit provides a stable output signal

for valve control on turbulent surface applications, such as feed water heaters,

flash tanks, and reactors.

Interface control on storage tanks

– The displacers are tolerant of

emulsions. They can track towards middle of emulsion, and are tolerant of

unstable interface. They also ignore vapor/liquid interface point above

displacer.

Mixing Tank – The displacer transmitter can also be used in harsh

production environments like those in a mixing tank. It provides a stable

output, easier to configure and is resistant to heavy surging caused by the

mixer.

Water elevation – The displacer can be used to maintain a water

elevation at a given height by sending out a proportional 3-15 PSIG signal

(over a 14 ″ control band) to a control valve to maintain water level at

midpoint by regulating the water flow rate out of the separator. The control

valve is fully open at 15 PSIG input and fully closed at 3 PSIG input.

You can also read: Ultrasonic Level Measurement Technology

In Summary the advantages and

limitations of Displacer transmitter include:

Advantages

- Stable signal in turbulent applications

- High Pressure/Temperature capabilities

- No flexure of pressure boundary part

Limitations

- Shifting SG can affect this technology

Some of the manufactures of Displacer level

transmitters include:

Sources: Magnetrol

Don't miss out on our Instrumentation updates, join our newsletter list here

No comments:

Post a Comment