Programmable logic controllers (PLC) play an

important role in automation sector. Various industries like Food &

Beverage, Chemical, Petrochemical, Power generation etc. use PLC.

Functions of each component:

CPU – This the unit that contains microprocessors

We have several types of PLC designs:

Compact PLC: This is built by several modules within a single

case. The I/O capabilities are decided by the manufacturer and not the user.

Modular PLC: This is built with several components that are

plugged into a common rack or bus with extended I/O capabilities. It contains

power supply module, CPU and other I/O modules that are plugged together in the

same rack, which are from the same manufacturers or from different

manufacturers.

Soft PLC: This is an advanced PLC system that consists of

compact, rack mounted components such as power supplies, I/O modules and a CPU

which embeds a powerful PLC Control software.

Programming Languages of PLC

There are several programming languages used to

write programs in a PLC. They include but not limited:

- Ladder Diagram

- Instruction List

- Functional Block Diagram

- Sequential Function Chart

- Structured Text

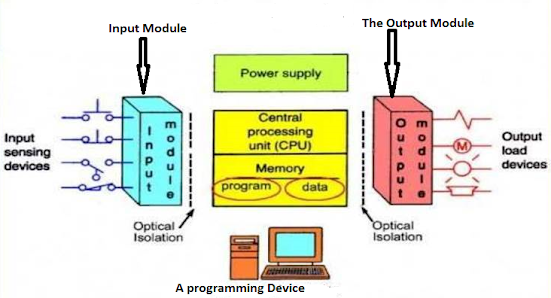

So what are some of the components that make up a Programmable Logic

Controllers?

|

| PLC System |

Functions of each component:

CPU – This the unit that contains microprocessors

Input and Output Sections – This is where the processor

receives information from external devices and communicates information to

external devices.

Power Supply Unit– It converts the Main AC voltage

to low DC voltage.

Programming device – Used to enter the required

program into the memory of the processor.

Memory Unit – This is where the program is stored

that is used to control actions.

The Operation of a PLC

Check the input status: First

the PLC takes a look at each I/O to determine if it is on or off.

Execute Program: Next the PLC executes

the program one instruction at a time.

Update output status: Finally

the PLC updates the outputs. It updates the outputs based on which inputs were

on during the first step.

Advantages of PLC:

- More flexibility

- Lower cost

- Increased reliability

- Faster response

- Easier to troubleshoot

- Communication capability

- Remote control capability

Disadvantages:

- They can render some jobs redundant

- They have a high initial cost

- If a Programmable logic controller stops, then the production stops

Industrial Applications of PLCs

- Food and Beverage industry

- Gas and Water Filling Stations

- Power Sector

- Bottling Plants

You can also read:

Some of the Top PLC Brands in the

world include:

Don't miss out on our Control and Automation articles, join our Newsletter list here.

No comments:

Post a Comment