Electromagnetic flowmeters are widely used in industrial process flow measurement. These meters come with several features for example: they offer non-invasive flow measurement, they can measure reverse flows and are insensitive to viscosity, density and flow disturbances. Additionally, electromagnetic flowmeters can respond swiftly to flow changes and are linear devices for a wide range of measurements.

Working Principle of the Electromagnetic Flowmeter

Electromagnetic

flowmeter operation is based on Faraday’s law of electromagnetic induction. The

induced voltages in an electromagnetic flow meter are linearly proportional to

the mean velocity of liquids or to the volumetric flow rates. As in the case in

many applications, if the pipe walls are made from non-conducting elements,

then the induced voltage is independent of the properties of the fluid.

Faraday’s

law of induction states that if a conductor of length l (m) is moving with a

velocity v (m/s) perpendicular to a magnetic field of flux density B (Tesla)

then the induced voltage (e) across the ends of a conductor can be expressed

by:

e =

Blv

This is

demonstrated in the figure below:

|

| Figure 1.0 The Operational principle of electromagnetic flowmeter |

In the above

illustration, the magnetic field, the direction of the movement of the

conductor, and the induced emf are all perpendicular to each other.

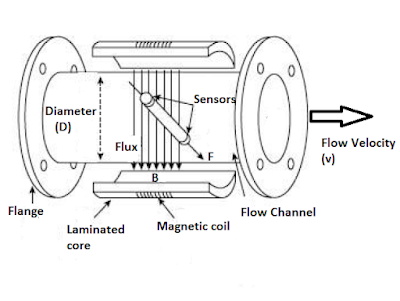

Let’s consider a simplified electromagnetic flowmeter construction below:

|

Figure 1.1 Construction of practical electromagnetic flowmeter

The

externally located electromagnets create a homogenous magnetic field (B)

passing through the pipe and the liquid inside it. When a conducting flowing

liquid cuts through the magnetic field, voltage is generated along the liquid

path between the two electrodes positioned on the opposite sides of the pipe.

The

conductor is the liquid flowing through the pipe, and the length of the

conductor is the distance between the two electrodes, which is equal to the

tube diameter (D). The velocity of the conductor is proportional to the mean

flow velocity (v) of the liquid. Hence, the induced voltage becomes:

e = BDv

If the

magnetic field is constant and the diameter of the pipe is fixed, the magnitude

of the induced voltage will be proportional to the velocity of the liquid. If

the ends of the conductor, in this case the sensors that are connected to an

external circuit, the induced voltage causes a current, i to flow, which can be

processed appropriately as a measure of the flow rate.

Electromagnetic

flowmeters are often calibrated to determine the volumetric flow of the liquid.

The volume of liquid flow Q can be related to the average fluid velocity as:

Q = Av

Where A is

the area of the pipe, which can be written as:

That gives the induced

voltage as a function of the flow rate:

We know that fluid velocity

v = Q/A

We can derive the

induced voltage as:

Equation 1.4 indicates

that in a well-designed electromagnetic flowmeter, if all other parameters are

kept constant, the induced voltage is linearly proportional to the liquid flow

only.

Even though the induced voltage is directly proportional to the mean value of the liquid flow, the main problem in the use of electromagnetic flowmeters is that the amplitude of the induced voltage is small relative to extraneous voltages and noise. The noise sources include:

- Capacitive coupling between signal and power circuits.

- Stray voltage in the process liquid.

- Capacitive coupling in connection leads.

- Inductive coupling of the magnets within the flowmeter.

- Electromechanical emf induced in the electrodes and the process fluid.

Key Merits of Electromagnetic Flowmeters

The electromagnetic flowmeters have the following advantages:

- The output (voltage) is linearly proportional to the input (flow).

- There is no obstacle to the flow path which may cause reduction in pressure.

- The electromagnetic flowmeter can measure flow in pipes of any size provided a powerful magnetic field can be produced.

- The output is not affected by changes in the characteristics of the liquid such as pressure, viscosity, and temperature.

Shortcomings of Electromagnetic Flowmeters

The electromagnetic flowmeters have the following limitations:

- The conductivity of the liquid being measured should not be less than 10 μꭥ/m. It is important to note that most water based/aqueous solutions are adequately conductive while a majority of hydrocarbons solutions are not sufficiently conductive.

- The operating cost is usually very high in an electromagnetic flowmeter specifically if heavy slurries are handled.

No comments:

Post a Comment