Essential components in any controlled automation

system include:

- The actuator (which does the work)

- The controller (which ”tells” the actuator to do the work)

- The sensor (which provides the feedback to the controller so that it knows the actuator is doing work)

An example of a simple controlled automation system

is shown below:

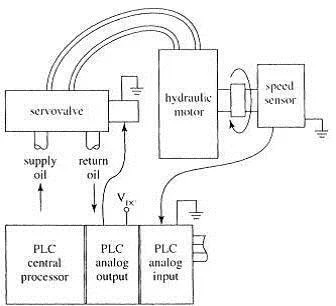

A controlled system may either be analog controlled

system or digital controlled system. Let's consider the following analog controlled

system:

The actuator is a hydraulic servovalve and a fluid

motor. The servovalve opens proportionally with the voltage it receives from

the controller and the fluid motor rotates faster if it receives more hydraulic

fluid. There is a speed sensor connected to the motor shaft, which outputs a

voltage signal proportional to the shaft speed. The controller is programmed to

move the output shaft at a given speed until a load is at given position. When

the program requires the move to take place, the controller outputs an

approximately correct voltage to the servovalve, then monitors the sensor’s

feedback signal. If the speed sensor’s output is different from expected i.e.

indicating wrong motor speed, the controller increases or decreases the voltage

supplied to the servovalve until the correct feedback is achieved. The motor

speed is controlled until the move finishes. As with any other control system,

the program may include a function to notify a human operator if speed control

isn’t working.

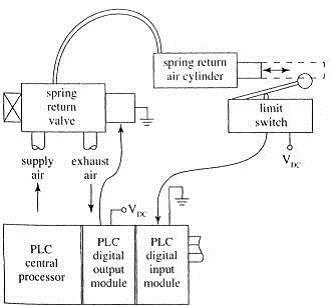

Having looked at analog controlled system above, let's now consider an example of a digital controlled system:

The above figure represents a simple digital

controlled system in which the actuator consists of a pneumatic valve and a

pneumatic cylinder that must be either fully extended or retracted. The

controller is a PLC that has been programmed to extend the cylinder during some

more complicated process and to go on to the next step in the process only

after the cylinder extends. When it is time to extend the cylinder, the PLC

supplies voltage to the valve, which should open to provide air to the

cylinder, which then extend. If all goes well, after a short time the PLC will

receive a change in voltage level from the limit switch, allowing it to execute

the next step in the process. If the voltage from the switch does not change

for any reason ( faulty valve or cylinder or switch, break in a wire,

obstruction preventing full cylinder extension etc.), the PLC will not execute

the next step. The PLC may even be programmed to turn on a “fault” light when

such a delay occurs.

Don't miss out on our Industrial Instrumentation & Automation updates, join our Newsletter list here.

Don't miss out on our Industrial Instrumentation & Automation updates, join our Newsletter list here.

No comments:

Post a Comment