Instrumentation is a science that deals with

measurements and control of processes. Instrumentation is applied in almost any

field from Medical, Manufacturing of pharmaceutical drugs, to simple processes

like temperature control in homes using Thermostats. Note that if we can’t

measure it then we have no need of controlling it.

You can also read: Basics of a Control Loop

Measurements can be in form of Fluid pressure, Fluid

volume, Fluid Flow rate, Temperature, Electrical voltage or current, Chemical

concentration etc. Once we have the quantity of the measured value, we

then transmit a signal representing this quantity to an indicating or

computing device where either human or automated action then takes place. If

the controlling action is automated, the computer sends a signal to a final

controlling device which then influences the quantity being measured. The final

control device can be in the form of:

- Electric motor

- Control valve-for throttling the flow rate of a fluid

- Electric heater

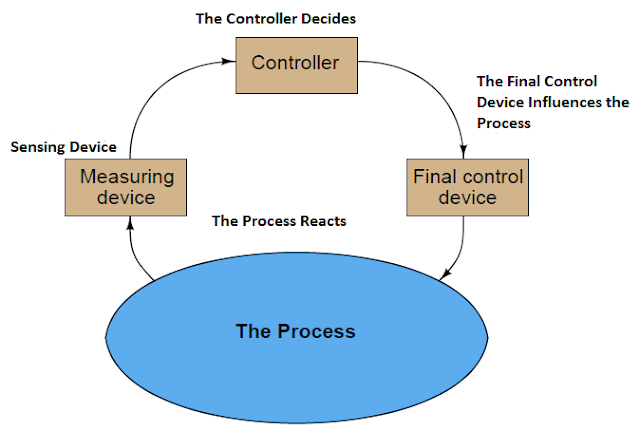

The measurement device and the final control device

connect to some physical system called the process.

|

| Block Diagram of a Process Control System |

- The measuring device senses

- The Controller decides

- The final control device influences the process

- The process reacts to the influence of the final control

You can also read: Basics of a Control Loop

So in a nutshell this is what we call a Process

control system.

Don't miss out on key updates, join our newsletter list here.

No comments:

Post a Comment